Reliable Materials Handling Solutions for Safer and Faster Workflows

Handling materials the wrong way can slow down operations and hurt workers. According to Safe Work Australia, manual tasks like lifting, carrying, and pushing are behind over 20% of serious workplace injuries in warehousing and transport. To reduce risk and speed up daily work, more businesses are focusing on better tools and smarter planning.

Every year, thousands of workers in Australia get hurt while lifting, pushing, or moving items at work. Many of these injuries happen because of poor materials handling, when the right tools aren’t used to move goods safely.

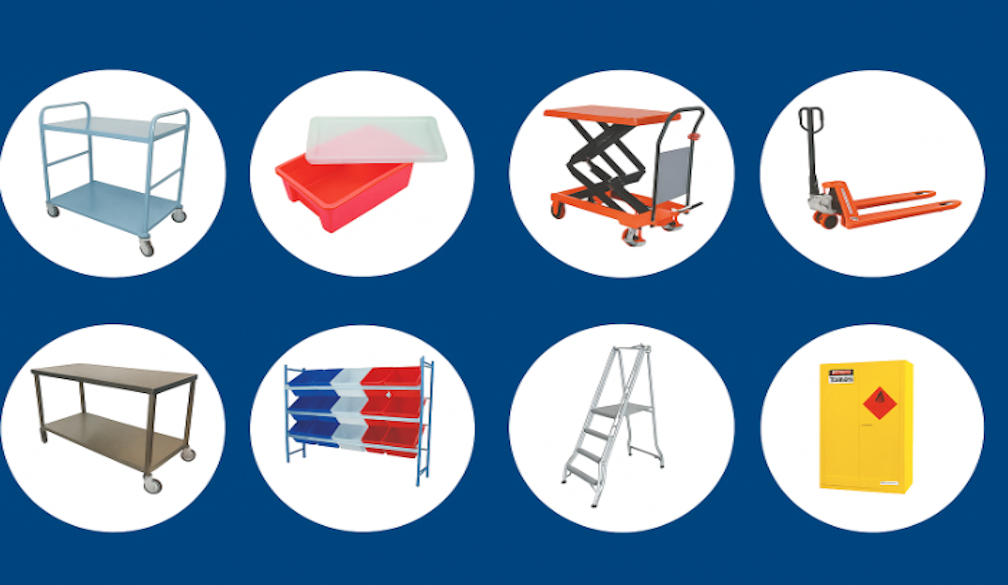

This includes trolleys, castors, carts, and equipment designed for moving goods in places like warehouses, hospitals, or retail storage rooms.

What Is Materials Handling?

Materials handling refers to how goods are moved, stored, protected, and controlled in workplaces like factories, distribution centers, and retail storage rooms. This includes equipment like:

- Manual trolleys

- Powered lifters

- Forklifts

- Conveyors

- Storage systems

It also covers how people use this equipment, such as pushing, lifting, and transporting items around the work area.

Why It Matters

Without proper materials handling, businesses risk delays, damaged goods, and higher injury rates. Workplace injuries often happen when workers carry or move items the wrong way or without the right equipment. That’s why making small improvements can bring major benefits.

Common Problems in Materials Handling

Even today, many companies still rely on outdated tools or manual methods. These issues show up often:

- Overloaded trolleys that tip over or become hard to push

- Worn-out castors that make movement harder and less safe

- Uneven flooring that causes vibration or load shifting

- Poor layout in warehouses that slows down movement

These small problems often lead to big consequences — from time lost due to slow movement to injuries caused by strain or equipment failure.

How Better Equipment Improves Safety

Using high-quality equipment for materials handling helps reduce accidents. Here’s how:

Safer Transport

Modern trolleys and carts come with brake systems, anti-tip features, and strong frames that protect workers. They also roll smoothly, requiring less force to move even heavy loads.

Better Posture Support

When workers have the right tools, they don’t need to lift, twist, or strain their backs. For example, adjustable height platforms allow better posture when loading or unloading.

Fewer Repairs

Stronger castors and stable frames last longer. They also handle different surfaces better, which reduces the risk of falls or spills.

Faster Operations with Smart Handling Tools

Speed is key for logistics and supply chains. Improved materials handling tools save time in three major ways:

Easier Movement

High-performance castors glide over surfaces with less resistance. This cuts down the effort needed to push or pull carts.

Custom Storage

Storage trolleys or carts designed for specific items mean workers don’t waste time finding or rearranging stock.

Reduced Downtime

When equipment works well, operations run without interruptions. There’s less chance of wheel locks, broken handles, or alignment issues.

Using Castors and Trolleys to Your Advantage

Castors are one of the most overlooked parts of materials handling gear. But they play a huge role in how smoothly equipment moves.

What to Look For in a Castor

- Wheel diameter: Larger wheels move better over rough surfaces

- Material: Rubber for quiet rolling; nylon for higher loads

- Swivel range: Allows carts to turn easily in tight spots

- Load capacity: Important to prevent breakdowns

TENTE castors, for instance, offer a wide range designed for specific tasks — whether that’s heavy load transport in factories or silent wheels for hospital carts.

Trolley Types That Work Best

Not all trolleys are the same. Choosing the right design depends on your environment:

- Platform trolleys – good for large, flat items

- Shelf trolleys – great for tools or smaller boxed items

- Cage trolleys – secure items and prevent them from falling

- Foldable trolleys – easy to store when not in use

By matching the right trolley to the task, you reduce errors, save time, and protect workers.

Who Benefits the Most?

Here are some industries where better handling tools can make major improvements:

Retail

Stores rely on quick restocking. Using quiet wheels and agile carts helps workers move items without disturbing customers. Strong brakes keep loads in place when stocking shelves.

Healthcare

Hospitals require sterile, smooth-moving carts. Special castors avoid floor damage and support infection control standards.

Manufacturing

Factories benefit from custom-built transport units that handle parts, tools, and raw materials. When workers can move items efficiently, it speeds up assembly and reduces waste.

Logistics

Distribution hubs depend on fast sorting and movement. Modular trolleys and ergonomic handling gear cut down on manual lifting and speed up delivery cycles.

Small Changes That Make a Big Difference

Improving materials handling doesn’t always mean a full system upgrade. It can be as simple as:

- Replacing worn-out wheels

- Adding brakes to trolleys

- Rearranging shelving layouts

- Getting height-adjustable carts for heavy lifting

These changes boost safety and save time without major expense.

Planning for Smarter Handling

If you're planning to update your facility’s materials handling setup, start by looking at these points:

- Weight requirements – Know the average and maximum weight loads.

- Work environment – Wet, hot, or dusty areas need special materials.

- Movement paths – Tight corners or long distances call for different designs.

- Worker comfort – Tools should support safety and reduce physical strain.

- Flooring – Match wheel types to surface material for best results.

You don’t always need large upgrades — sometimes replacing poor-quality wheels or switching to a better trolley can make an instant difference.

Environmental Impact of Better Handling

Using longer-lasting carts and wheels cuts down on replacements and reduces landfill waste. Strong, tested equipment also lowers the risk of goods being damaged, saving both product and packaging.

Some equipment is also designed with recyclable parts and energy-saving features in powered options, which help businesses meet environmental targets.

Why It Matters More Now Than Ever

As business needs grow, the way goods move inside facilities must keep up. Better handling means:

- Less downtime

- Fewer injuries

- Lower long-term costs

- Smoother workflows

A small investment today in reliable trolleys or better castors can prevent bigger problems tomorrow.

TENTE Product Range for Smart Materials Handling

TENTE provides industrial-grade materials handling equipment such as heavy-duty trolleys, medical castors, and ergonomic transport systems.

Their products are made to last and perform reliably across industries, from warehousing and retail to medical and manufacturing environments. They help reduce friction, improve load control, and increase workplace safety.

Final Thoughts:

Delays, injuries, and damaged goods often trace back to poor handling systems. Whether you're managing a warehouse, retail store, hospital, or production line, better equipment leads to better results. Don’t wait for small problems to turn into bigger expenses.

Start improving your materials handling today with trusted tools that support your team, protect your stock, and keep operations moving. Visit TENTE materials handling solutions to find high-quality castors, trolleys, and transport equipment designed for real-world use.